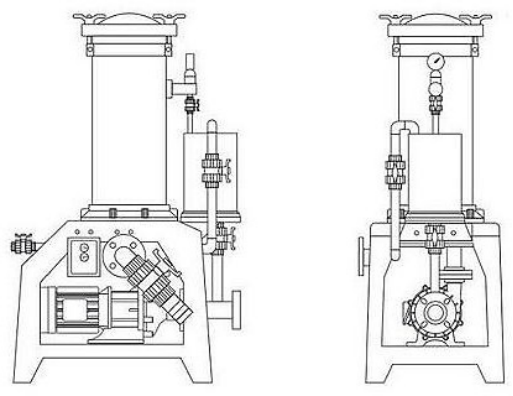

Chemical Filter/ plating filter/ chemical industrial filter

Brand Glorious

Product origin China

Delivery time Within 20 days

Supply capacity 1000units 1 month

Application:

galvanizing, nickel plating, chrome plating, acid copper plating, coke copper plating, alkaline copper plating, and so on

Description

The electroplating filter is to press the impurities into the filter bucket by pumping, and remove the impurities through the filter element to obtain a high-precision clean potion. Electroplating filter is widely used in electroplating, chemical, petroleum, pharmaceutical, and other industries.

Instructions for use

1. Check whether the access piping has been installed before use, and fix the access piping in the slot so that it is not easy to swing.

2. Open the exhaust valve screw and water injection valve, the water from the water injection cylinder into the pump and the inlet tube through the water injection valve, so that the inlet tube is completely filled with liquid, or open the upper cover handle to remove the upper cover, the water is injected through the filter cylinder, so that the inlet tube is completely filled with liquid.

3. Check whether the voltage and motor voltage are correct before starting the motor to prevent errors.

4. Lock the water injection valve before starting the motor and then open the exhaust valve screw so that the gas can be discharged from the catheter.

5. The liquid in the water injection cylinder flows through the water injection valve into the pump, and then lock the water injection valve after there is no liquid in the water injection cylinder.

6. Before the filter is used, check whether the pressure gauge is filled with clean water or oil in the fixed seat. Please fill the water and then lock the pressure gauge to maintain the accuracy of the pressure gauge.

7. After the above actions are completed, start the pump motor to start running, and pay attention to whether the running direction is correct. If the running direction is wrong and the liquid cannot be discharged, please replace the two-phase power supply to change the running direction.

8. Check whether the inlet and outlet pipelines are selected correctly before starting the power supply.

For example: whether the access valve is opened, whether the pipeline flow route is correct, whether the liquid in the liquid tank is normal, and whether the pipeline is damaged.

9. Operating in dangerous environments or liquids, whether to wear protective clothing and protective masks, safety shoes and socks.

10. Check the protection switches. For example, whether the liquid switch, the liquid level in the tank is normal, and whether the power protection switch is in the normal operating position.

Please provide more detailed information, we can recommend further customized rectifiers. 1. What do you need the power supply for? 2. What is the input voltage in your country? How many phases? How many hertz? 3. What is the output voltage and current of the rectifier you need? 4. What type of rectifier do you need? High frequency, thyristor, or other? 5. What kind of power supply cooling me...more