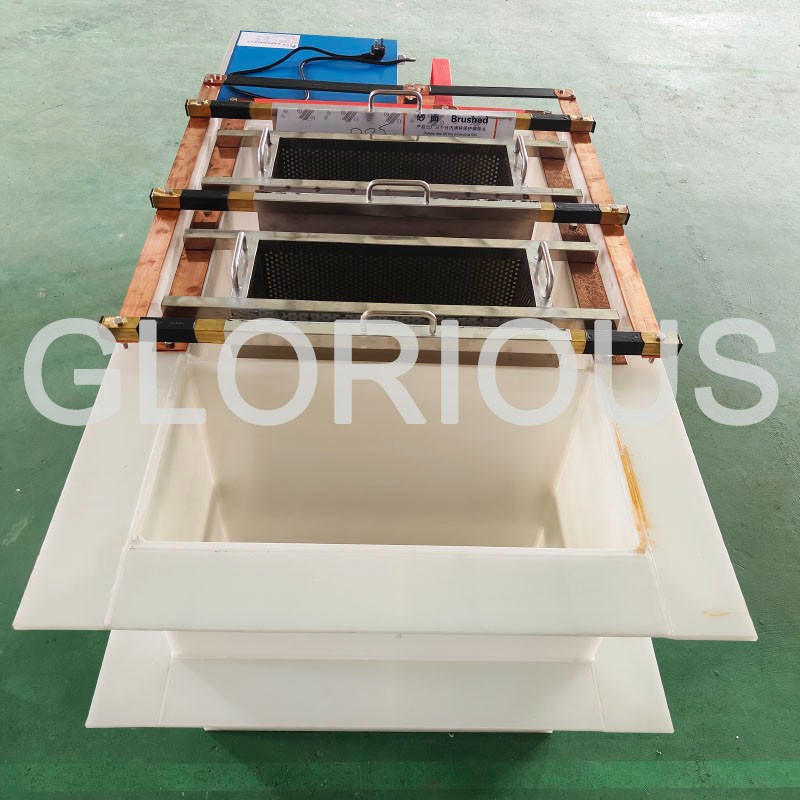

Automatic Stainless steel electrolytic polish production line/ SUS304 electro polishing machine

Brand Glorious

Product origin China

Delivery time Within 20 days

Supply capacity 100 units 1 month

① The surface will not be corroded

② Applicable to products of various shapes and sizes

③ Short polishing time and high production efficiency

Working principle of stainless steel electropolishing:

Under certain temperature, voltage and current density (generally less than 1A/cm2), the tiny protrusions on the surface of stainless steel products are dissolved, making the stainless steel surface smooth and flat with a certain brightness.

Power supply type: DC power supply

Positive electrode: product

Negative electrode: stainless steel plate

Electrolytic solution: chemical synthetic solution such as sulfuric acid and phosphoric acid

Features of electrolytic polishing:

■ The product is polished thickly, and no deterioration layer will be produced on the polished surface

■ There will be no additional stress on the product surface, and the original stress layer can be removed or reduced

■ Various products can be processed, including hard materials and soft materials that are difficult to polish mechanically, thin-walled products, complex shapes, and small parts, etc.

■ The electropolishing time is short, and many products can be polished at the same time, with high production efficiency

■ The surface roughness that can be achieved by electrolytic polishing is related to the original surface roughness

Application scope of electrolytic polishing:

■Metal products and parts with small surface roughness, such as reflectors, decorations, injection needles, springs, blades and stainless steel pipes, stainless steel tanks, stainless steel plates, etc.

■Stainless steel machined products

■Stainless steel products for medical equipment, food-grade stainless steel tableware

■Bakelite molds, glass molds, metallographic grinding discs

Please provide more detailed information, we can recommend further customized rectifiers. 1. What do you need the power supply for? 2. What is the input voltage in your country? How many phases? How many hertz? 3. What is the output voltage and current of the rectifier you need? 4. What type of rectifier do you need? High frequency, thyristor, or other? 5. What kind of power supply cooling me...more