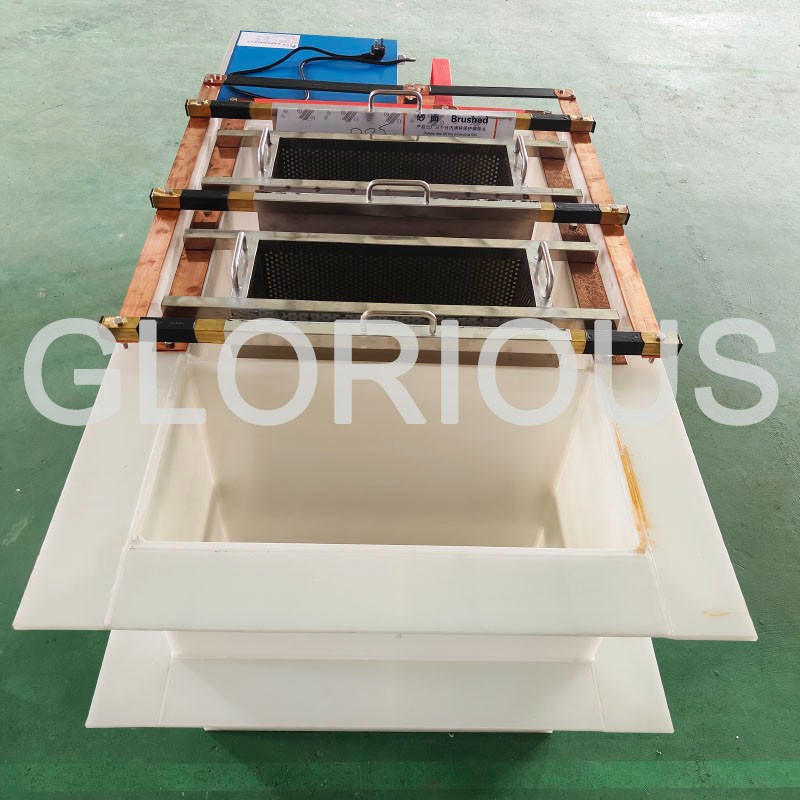

Stainless steel electr polish machine/ SUS304 electro polish machine/ stainless steel electropolish machine

Brand Glorious

Product origin China

Delivery time Within 20 days

Supply capacity 100 units 1 month

Application: SS201, SS304, SS316L

Feature: Polish the surface very shiny

How to control the temperature on Electro polishing process?

Temperature range:

Electrolytic polishing temperature is generally 50-70 degrees Celsius.

Heating: In the process of electrolytic polishing, the number of products polished by customers is small every day, and heating tubes and temperature control devices can be used. The heating tube can be electric heating tube.

Material of Heater: Since electrolytic polishing is mainly acidic liquid, in the selection of electric heating tubes, quartz heating tubes can be used when the equipment budget is too low, and Teflon heating tubes can be used when the customer has a sufficient budget.

Cooling method: If the continuous uninterrupted production temperature is too high, it needs to be cooled. For example, installing plastic cooling pipes, cooling pipes, using chillers, cold water towers, etc. (manual line is generally not used, automatic line is recommended to choose refrigeration equipment)

Description of electrolysis polish machine

Stainless steel electrolytic polishing is mainly for the surface bright treatment of stainless steel workpieces. Applicable to 201 stainless steel, 304 stainless steel, 316 stainless steel and other types of stainless steel surface polishing process.

How it works: The product that needs to be polished is the anode, and the insoluble metal is the cathode (such as lead plate). They are simultaneously immersed in the electrolytic cell, through direct current to produce selective anodic dissolution (product surface dissolution), the surface of the workpiece is gradually flattened. After this, the brightness of the product surface has been greatly improved. Can make the surface of the product more bright, and has a certain degree of deburring effect.

The surface finish after electropolishing is mainly determined by the surface quality and the finish before polishing. If the product before polishing is mirror-like, the polished product will be as bright as a mirror

No | Item | Specification |

Name | Stainless steel electro polish machine | |

2 | Include | Tank, rack, heater, cooling pipe, copper plate |

3 | Support machine | Rectifier, temperature control box. |

4 | Type | Manual / automatic |

5 | Operate | Manual need people operate by hands |

6 | Package | By wooden box |

7 | Payment item | By T/T, deposit: 50%, balance 50% should be paid before shipment |

Please provide more detailed information, we can recommend further customized rectifiers. 1. What do you need the power supply for? 2. What is the input voltage in your country? How many phases? How many hertz? 3. What is the output voltage and current of the rectifier you need? 4. What type of rectifier do you need? High frequency, thyristor, or other? 5. What kind of power supply cooling me...more