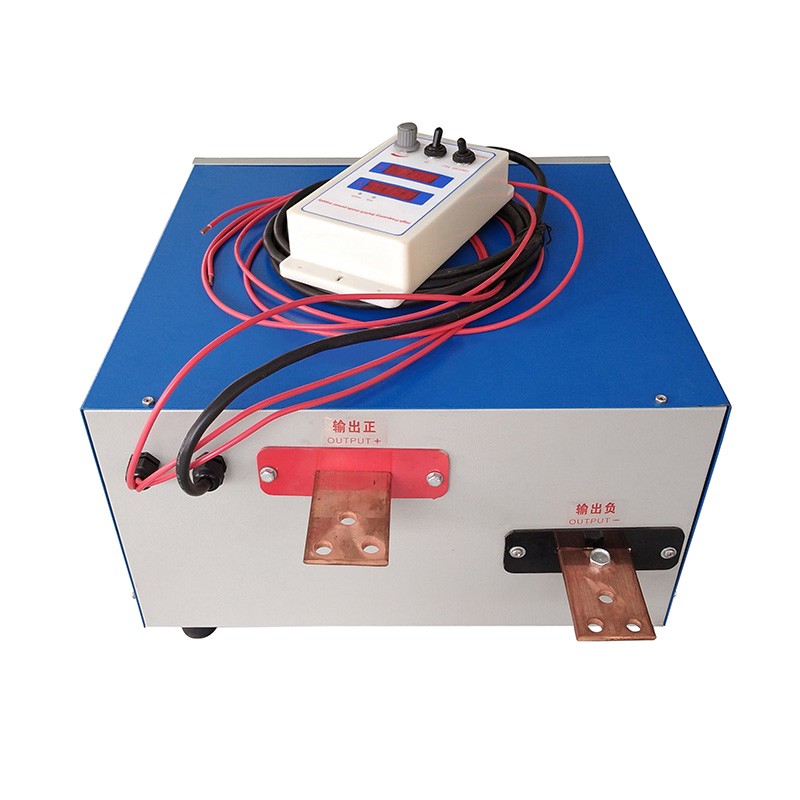

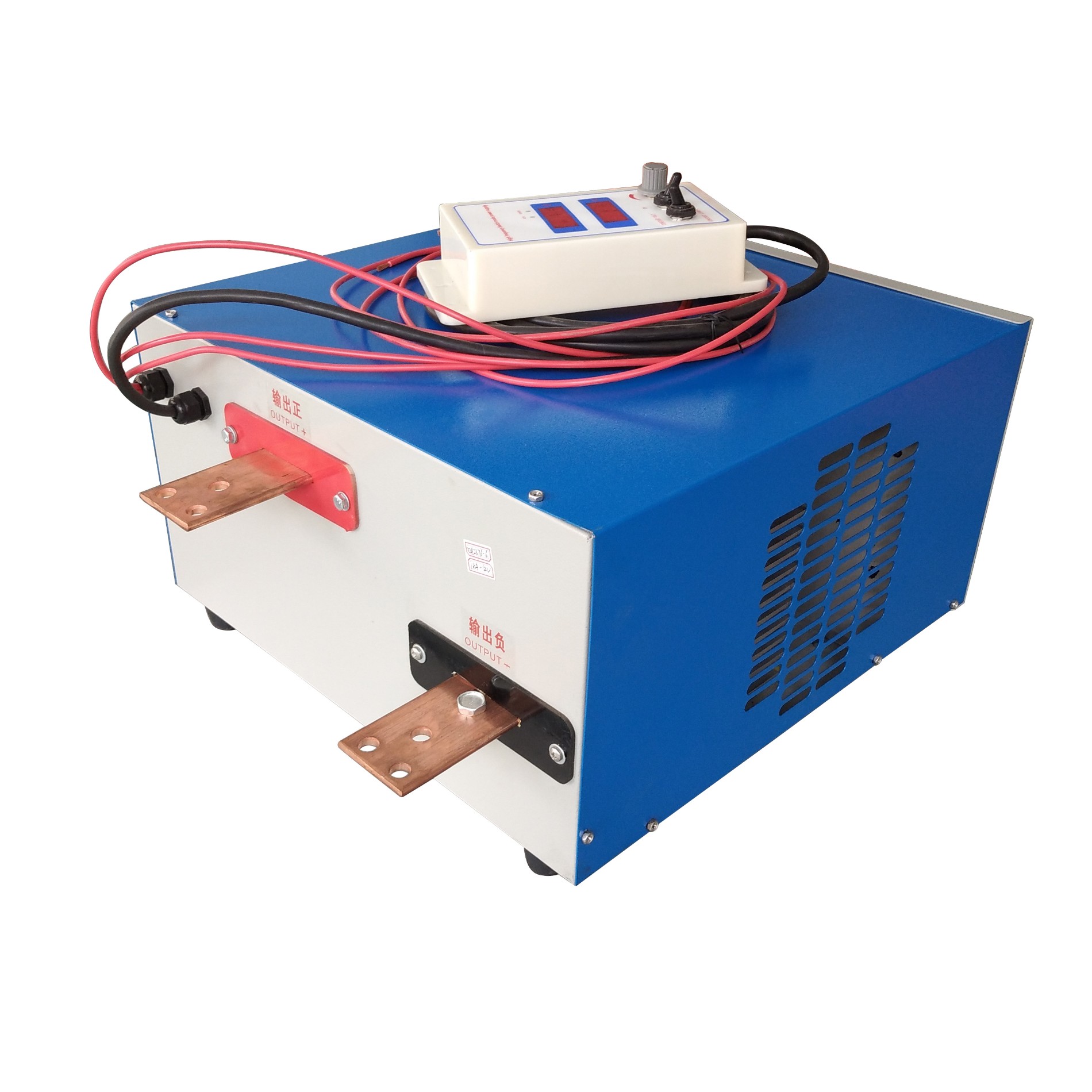

IGBT High frequency Rectifier Electroplating Power Supply Gold plating Rectifier

Brand Glorious

Product origin China

Delivery time Within 7 days

Supply capacity 1000unit 1 month

IGBT High frequency Rectifier

1. Rectifier Application areas:

1) Electroplating (zinc plating, nickel plating, copper plating, chromium plating, gold plating, silver plating, tin plating, etc.)

2) Electrophoresis (electrophoresis gold, electrophoresis rose gold, electrophoresis gun black, electrophoresis black)

3) Anodizing (aluminum, titanium anodizing, hard oxidation, micro-arc oxidation)

4) Electrolysis (electrolytic degreasing, electrolytic acid, electrolytic polishing, electrolytic nickel, electrolytic silver, electrolytic copper, electrolytic protection, electrolytic stripping, etc.)

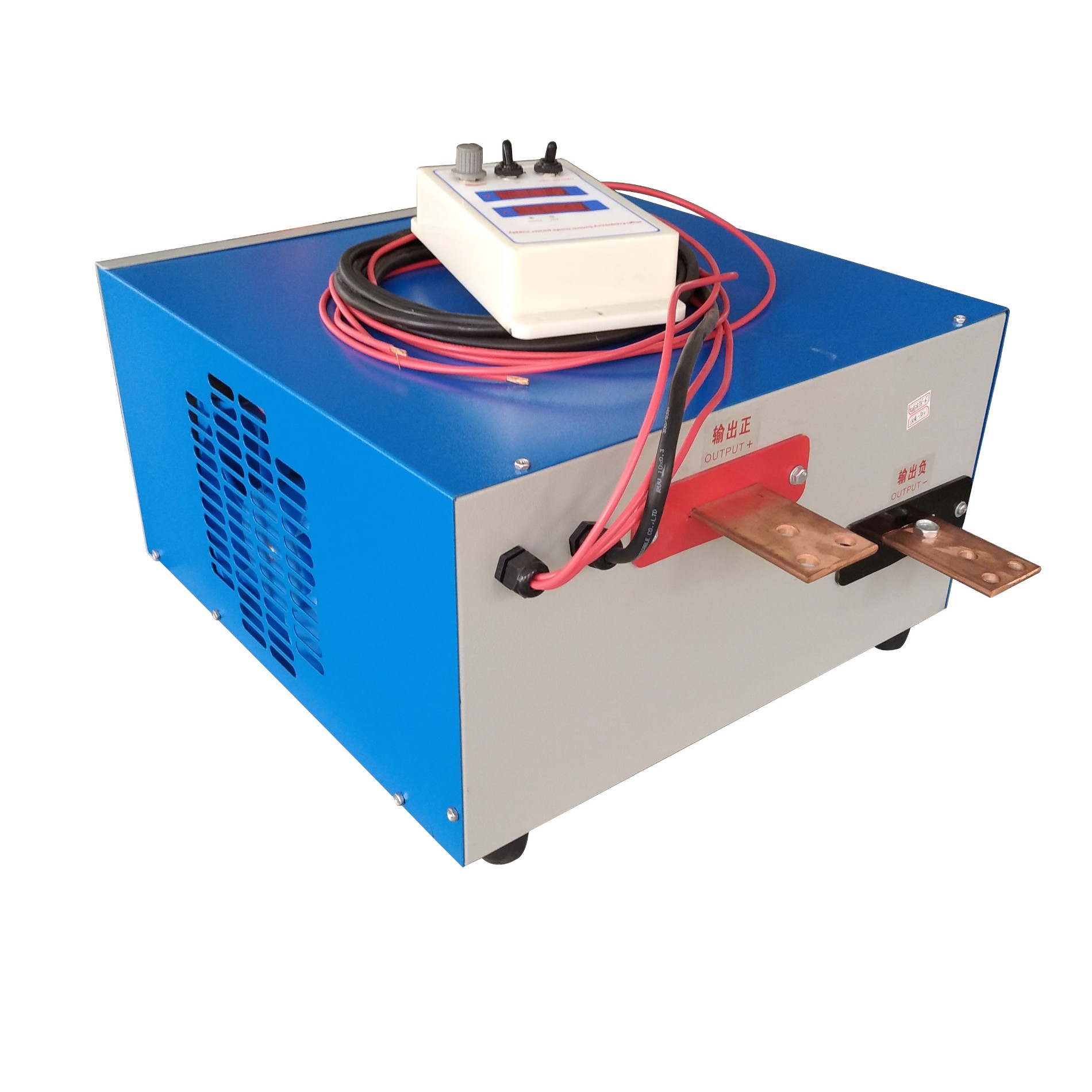

2. Rectifier Output: 0-50000A adjustable, 0-500V adjustable

3.Cooling method: air cooling, water cooling, oil cooling

Rectifier Description

Input Voltage | Single phase 220V/ 380V three phase 50-60HZ or customized |

Output Dc Current | 1A-30000A optional |

Output Dc Voltage | 3V-1000V optional |

Voltage Regulation Accuracy | <1% |

Steady Flow Accuracy | <1% |

Output Ripple | 1%-2% |

Cooling Method | Air-cooled or water-cooled |

Overall Efficiency | >90% |

Load Operation | 24 hours operation at full load |

The rectifier is mainly composed of rectifying filter circuit, full (half) bridge conversion circuit, PWM control circuit, Constant voltage, constant current, voltage limitation, current limitation, control protection circuit, and auxiliary power circuit

Main Features of Rectifier

1) The rectifier has a long service life and is durable, and can be used safely in harsh voltage environments and harsh humid environments.

2) The rectifier circuit is reasonably designed and has complete protection functions. Input AC undervoltage, overvoltage, phase loss protection, output overcurrent, overheating protection

3) The rectifier control circuit is sealed and anti-corrosion designed, small in size, light in weight, easy to load and unload, and easy to install and maintain.

4) The rectifier is partially made of plastic structure, which increases the service life of the power supply in harsh environments.

5) The rectifier has high efficiency, high precision, high stability and low ripple.

6) Steady current and voltage can be used. Output current and voltage can be adjusted separately.

7) The current density is high, the plating speed is faster, the workpiece coating is more delicate, smooth, glossy, high purity, uniformity, extensibility, wear resistance, corrosion resistance, saving metal materials and additives.

Our rectifier ( power supply) adopts the international advanced high frequency switching power supply technology, which is specially used for the high quality multi-functional dc power supply required by the industries of electroplating, electrolysis, aluminum oxidation, electrophoresis, water treatment, electroetching, heating, battery charging, printed circuit board and so on.

Please provide more detailed information, we can recommend further customized rectifiers. 1. What do you need the power supply for? 2. What is the input voltage in your country? How many phases? How many hertz? 3. What is the output voltage and current of the rectifier you need? 4. What type of rectifier do you need? High frequency, thyristor, or other? 5. What kind of power supply cooling me...more